|

|

Supercharger Efficiency

Last Updated: 05/16/2011

|

Types of Superchargers and their Efficiency

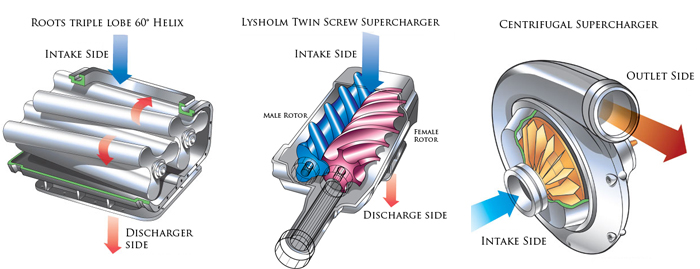

There are three main types of superchargers in today's automotive market, Root style, Lysholm twin screw and centrifugal, each one suited for a different application. While there are more types of superchargers i am only going to use the three most common types in this article.

First we need to know what exactly a supercharger is designed to do, while most of you many know what one does or how it works i would still like to state that a superchargers job is to force a larger mass of air into the same amount of volume into a engine, i will explain later the emphasis on mass and volume.

The Lysholm supercharger is the newest in design of a positive displacement supercharger and is more efficient that the roots style. the reason they are more efficient is because of the way they compress the air into the intake. Speaking in terms of physics, When ever u move, smash, compress anything, whether it be a solid, gas or liquid it causes the molecules of the substance to heat up, which causes the volume to expand but u still have the same amount of mass. For superchargers, the hotter the air gets the less you will have density wise going into each cylinder. So while a roots spin outwards towards the casing wall smashing the air as it spins and is then forced and compressed within the intake manifold, the newer twin screws has a male(blue) and female(pink) rotor that spins the air in between its rotors and much more fluidly, moving the air from the front to the back, compressing the air while it is still in the blower, reducing the friction and resistance caused by the air, reducing the heat as it enters the cylinders.

A centrifugal supercharger is nothing more than a turbocharger that is driven by the engine instead of the exhaust system, centrifugals work by spinning multiple blades and very high RPMs(much higher than roots or twin screw) to force air into the intake, they are much more efficient at high rpms compared to roots or twin screw but they lack low rpm boost and create much more heat.

A simple example of boost loss would be if you where to install a boost gauge in you manifold and block off the intakes, then heat the manifold from 70°F to 150°F the gauge would actually register an increase in boost, although obviously its not running any boost and you still have the same amount of air in the engine.

The faster you spin a supercharger the more it will heat up the air and the more the volumetric efficiency will drop but the boost will still show an increase. If you can build an engine to actually withstand it, you could theoretically spin a supercharger so fast and heat the air so much it would actually become parasitic to the engine. (I don't recommend that)

On the reverse side of intake modification, take an engine that runs NOS. NOS is used in high performance engine for short duration to temporarily increase hp, it works by being injected into the intake system and does two things, one it super-cools the air and two, when the nos enters the combustion chamber and reaches 296°C the nitrogen and oxygen atoms split releasing more oxygen so the air becomes more dense thus you are able to pack a larger mass of air into the same amount of volume.

You might be thinking though if u take a large 1471 blower and throw it on a engine you can spin it slower than a smaller 671 and still get the same amount of compression and since it is spinning slower it wont produce as much heat, and your right but you have to factor in the extra weight and resistance that the engine has to push, the heavier your components are, the more hp it will take to drive the supercharger.

Written by,

Garen Phillips

|

|